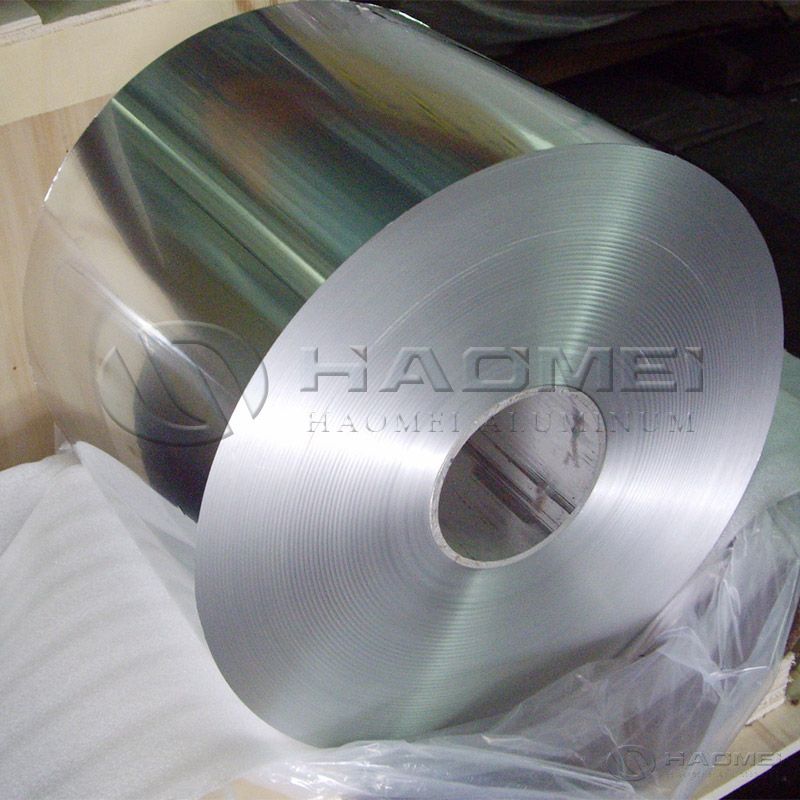

1235 aluminum foil is a commonly used aluminum alloy with aluminum content over 99.35%. It is also a kind of pure aluminum foil and is widely used in cables, tapes, and battery aluminum foils. It has good conductivity.

The tempers of 1235 aluminum for battery foil is H18. The typical thickness is 0.012-0.035. It is for lithium-ion battery current collector materials. It has good anti-rust properties, formability, and weldability, which is an ideal material for lithium ion battery.

Battery foil belongs to the fine processing of aluminum foil, and the precision requirements for the various properties of aluminum foil are very high. Therefore, the processing of battery foil is more difficult and the process requirements are higher, which are mainly reflected in the thickness, strength and surface quality requirements.

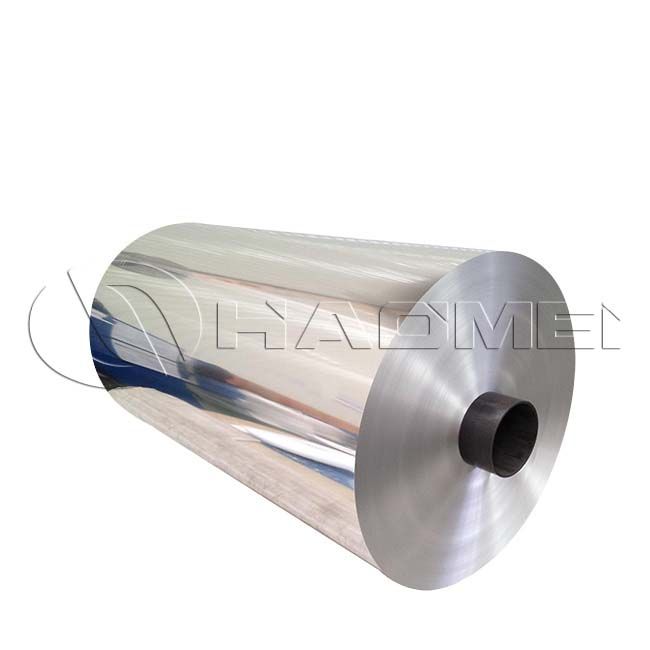

For the cigarette packaging, the temper of 1235 aluminum foil is O. The typical thickness is 0.006-0.007 mm. It is used for cigarette packaging after lining paper, printing or painting. The thickness of 1235-O aluminum foil for flexible packaging is 0.006-0.009 mm. It is for the packaging of candy, milk and dairy products, powdered food, beverages, tea, bread and various small foods, etc.

1235-O aluminum foil is also used for wrapping weak wires for shielding. The typical thickness is 0.006-0.04 mm. It is also used for electronic capacitor. The typical thickness is 0.0045-0.009 mm. Haomei Aluminum is a large-scale aluminum foil manufacturer, which can process 1235 aluminum foil with a thickness of 0.018-0.5mm, and the tempers are O and H18. Welcome to leave message below to inquire 1235 aluminum foil price.