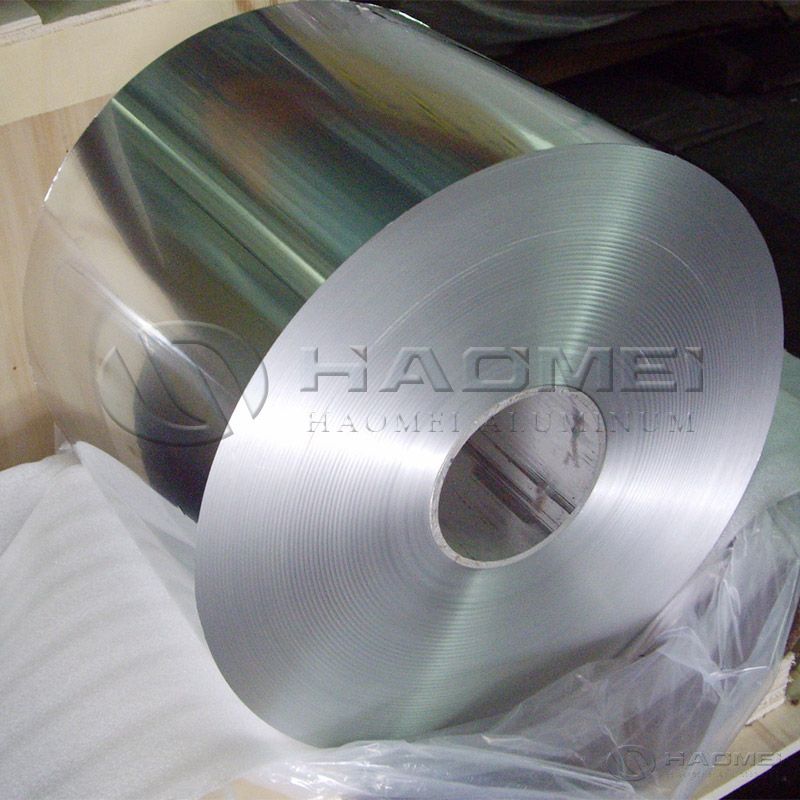

Aluminum foil jumbo roll refers to aluminum with a purity of more than 99.5% and a thickness of less than 0.2mm. The thickness of the aluminum foil for lamination is between 7 and 15 μm. As a packaging material, aluminum foil has the following advantages in addition to its extremely light weight:

1. It has strong light-shielding, high reflection ability to light and heat, and can be used as heat-proof insulation packaging.

2. It has good insulation and is impermeable to gas and water vapor, preventing the contents of the package from absorbing moisture, oxidizing and deteriorating, so it has better protection performance.

3. It has good shape stability at high temperature and low temperature.

4. Aluminum foil is easy to process. It can be used for printing, coloring, embossing, surface coating, gluing, lacquering, and processing with plastics and paper into composite materials.

The disadvantages of aluminum foil are that it cannot bear the load and has no sealing properties. The thin aluminum foil is easy to form pinholes and easy to wrinkle. However, if aluminum foil is laminated with paper or plastic, ll of the above problems can be solved, and its advantages such as insulation can be more fully utilized.

Aluminum foil bags are generally three-layer composite, that is, PET + pure aluminum + PE. But if it is a large aluminum foil bag, a four-layer composite is generally required, and nylon material is added on this basis.

Aluminum foil bags are usually used in the food industry, called food aluminum foil bags. They are generally used to package meat products, dried fish, seafood products, cured meats, roast duck, roast chicken, frozen food, ham, cured meat products, sausages, cooked meat products, pickles, spices, herbal fruits, nuts, etc.

Haomei Aluminum offers different alloys of aluminum foil for lamination like 3003, 8011, 1235, 1100,etc. Welcome to leave message below to inquire what you need.

Original Source: https://www.alumhm.com/a/aluminum-foil-jumbo-roll-for-laminated-foil-bag.html

没有评论:

发表评论